Effective Lighting Management: Group Relamping

Group relamping offers significant savings in time and labor costs over spot replacing failed lamps. Regularly scheduled maintenance based on projected lamp life and lumen depreciation keeps a lighting system functioning at its maximum by replacing all lamps at their economic life.

When you think that you have cut operating costs to the max, let us show you how you can do more with less. According to the U.S. Department of Energy (DOE), lighting can represent over 38% of the average commercial building’s electric bill.

Take it from our customers, a regularly scheduled group relamp of your building greatly reduces your material and labor costs. Many lamp manufacturers offer a warranty for group relamp projects that provide you with the product warranty of up to two years. Industrial Light and Power has established a relationship with Sylvania Lighting to ensure a smooth, hassle-free warranty program for you. And, we maintain a database of information for our customers, so your product information is easily tracked. Industrial Light and Power also retrofits complete lighting systems to reduce daily electrical costs while at the same time delivering a safer, better lit, more productive work environment.

Energy-saving lighting solutions are available that reduce your costs while maintaining or improving lighting quality. The Energy Savings Cost Council reports that these projects have an average payback of 2.2 years and a 45% return on investment. Group relamping is a process that saves money when fluorescent, high-pressure sodium or metal halide lighting is used. All lamps in a group are replaced at the same time rather than one at a time on failure. Using group relamping has been found to reduce relamping costs by 50%. Whether your staff does group relamping or you ask Service Lamp to provide the service, group relamping is a cost-effective way to keep your lighting in top shape.

Why Group Relamping Works:

You know from experience that incandescent lamps fail at random. Service life for bulbs is an average so half the bulbs will fail before the service life stated on the package. Incandescent lamps can fail at random and far short of the average because of the filament. Physical shock or vibration for example will cause a lamp failure. Power spikes can also dramatically shorten the bulbs life.

High intensity discharge lamps and fluorescent lamps, do not use a filament to generate light. The processes used to generate light are predictable such that most lamps will need to be replaced near the end of their rated life. Ballasted lamps are perfect candidates for group relamping.

The predictability of this class of lamps also enables us to project lumen depreciation. Lumen depreciation simply means that an old lamp is not as bright as a new lamp. Over time the business still pays 100% for electricity but may only get 30% of the light output from a depreciated metal halide lamp. Lower light levels due to lumen depreciation or dirt accumulating on the lamp or fixture are important considerations for group relamping.

Another consideration for group relamping is the effort required to change a lamp. This type of lighting is generally high above the floor. On the retail sales floor merchandise needs to be moved to change a lamp. Changing bulbs during work hours in offices or production areas means disrupting work flow. Service Lamp can arrange for group relamping to take place overnight with zero production or sales lost.

How Group Relamping Works:

Group relamping means replacing all light bulbs at one time completely or in an area of the a store or warehouse. The advantage of group relamping is about a 50% savings in labor costs when compared to replacing lamps on failure. There are other tasks performed during group relamping that are common sense aspects of facility management.

The other advantage of group relamping is that it is easier to meet storage and handling requirements for ballasts and spent lamps containing mercury. Lighting products replaced during the group relamping process are removed by our service or can be shipped to the recycler immediate after removal. Spot replacement generally accumulates spent lighting product over a long time.

Industrial Light and Power can meet your group relamping needs by providing quality lighting products for your maintenance department or a complete package including labor. Qualified technicians and electricians will be dispatched to your property with all the materials necessary to complete the job. Typically an entire property can be done overnight and ready to open the next morning.

Group Relamping Technology Upgrades:

Performing a large scale group relamping while also changing lighting technology to LED is the best way to achieve the benefits of group relamping while also adding energy savings, higher quality light output and longer life making it the ultimate group relamping option!

By changing all metal halide, mercury vapor, high pressure sodium, fluorescent or induction fixtures to LED via an LED retrofit kit or a new LED fixture you are enhancing all aspects of your facility lighting system at one time. While upfront costs are usually a bit higher with a conversion to all LED, the cost savings in energy usage and extended lamp life far outweighs the additional upfront costs. And additionally, the quality of LED lighting is a major improvement over older lighting technologies which increases productivity, security, appearance and customer appeal.

- Lighting system paybacks often range from one to four years with return on investment (ROI) ranging from 5-25%*

- Improve safety and reduce energy usage

- Increase system control with energy-saving occupancy sensors

- Improve employee productivity and sales by enhancing light quality in work and retail areas

- Reduce cooling loads – less waste heat is given off by new technology lamps and ballasts

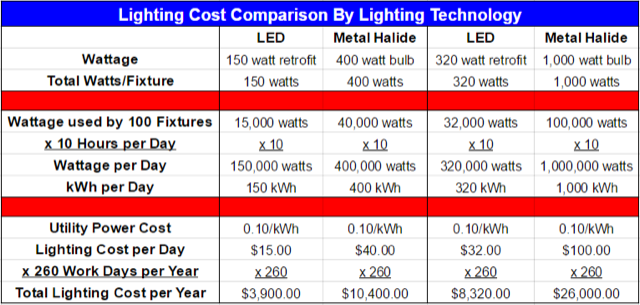

Here is an example of the cost savings between LED and Metal Halide technology:

Group relamping from Industrial Light and Power….Illuminating your world…….

How Can We Help?

Industrial Light and Power is here to answer any questions that you may have. We take pride in our adaptability and service so if you don’t see something you’re looking for feel free to ask us about it.